From:sochi

I. Introduction of Drilling Gear

Common drilling types and meanings:

PTH - Plating through holes: Holes in which the walls are coated with metal and are used to connect the conductive pattern of the intermediate or outer layer.

NPTH - Non-plated through holes: Holes in which the walls are not metal-plated and are used for mechanical mounting or mechanical fixing of assemblies.

VIA - Via holes: Plated through holes for electrical connections (e.g. buried holes, blind holes, etc.) between conductive patterns in different layers of the printed circuit board, but not for cartridge assembly leads or other reinforcing materials.

Blind holes: Via holes extending to only one surface of printed board.

Embedded holes: Via holes not extending to the surface of printed board.

Hole Damage

The reasons are: Take the drill bit after breaking the drill; There is no aluminum sheet or clamp reverse bottom plate when drilling; Parameter error; drill bit elongation; The effective length of the drill bit cannot meet the thickness of the drilling stack; Hand drilling; The material for the plate is special, caused by extra materials.

Solutions:

Conduct troubleshooting according to the previous problem 1, find out the cause of knife breakage, and make correct treatment.

Both aluminum sheet and plate play the role of protecting the hole ring. During production, the available and unavailable plates must be placed separately and uniformly. The plate shall be checked again before installation.

Check whether the drilling depth meets the requirements and whether the parameters of each drill tip are set correctly before drilling.

Check whether the position of the drill bit clamp is correct before starting the drilling rig when the drilling rig grabs the drill bit, the drill bit shall not exceed the presser foot when starting the drilling rig.

Visually inspected the effective length of the drill bit before installing the drill bit, and measure and check the number of stacks of available production plates.

If the accuracy and speed of manual drilling and cutting cannot meet the requirements, manual drilling is prohibited.

Select the parameters appropriately according to the quality when drilling special plates and setting parameters, and do not feed the cutter too fast.

Kunshan ISOCHI Electronics main products are listed as follows:

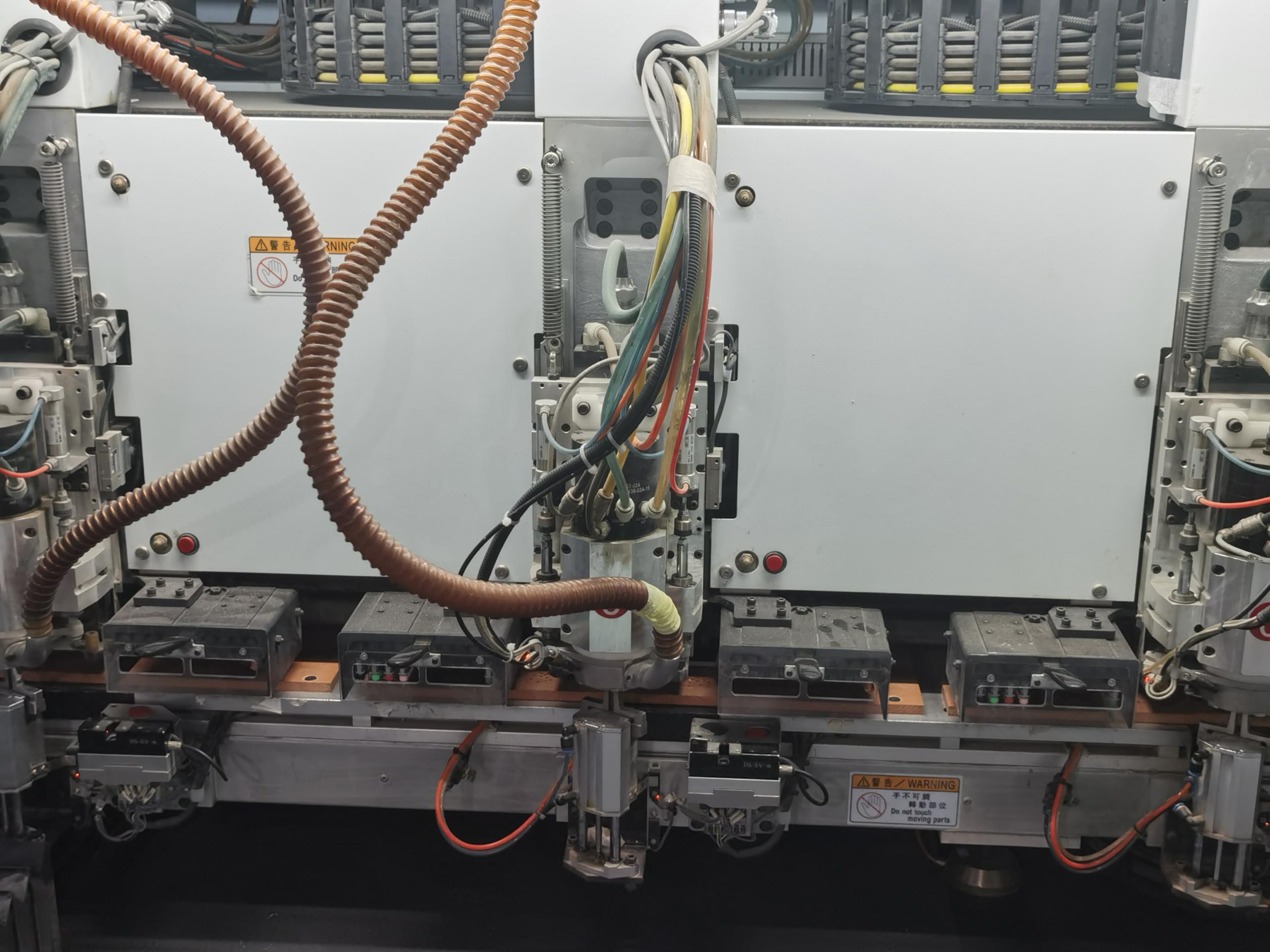

1. Equipment: PCB drilling machine, PCB forming machine, X-ray inspection machine, V-cut machine, etc;

2. Accessories and consumables: major PCB numerical control drilling machines for Mitsubishi/Hitachi laser drilling machine accessories, Japan Hitachi, Germany SCHMOLL, Taiwan TONGTAI, TALIANG, ANDERSORN and TAKISAWA, Germany POSALUX, American EXCELLON, PLURITEC, HANS, VEGA, Aisite, Xingweike, Dali, Dongxing, Tianma, QH Quartz and so on, as well as molding machine inspection series accessories including focusing mirror, scanning mirror, laser head, XYZ axis motor, PR mirror, MCU base plate, IO card, RU4B servo card, Tuma card, M22 servo board, presser foot cup, manipulator, knife break detection board, optical fiber, inductor, amplifier, knife detector, cylinder, collet, knife base, cutter head, pressure foot pad, tube cleaning brush, brush, rubber roller, grinding brush, filter element, collet wrench, dust suction pipe connector, pin, lubricating grease and electric board;

3. Processing and customized service for non-standard products of precision spare parts; Equipment maintenance, spindle maintenance, etc.